Categories

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

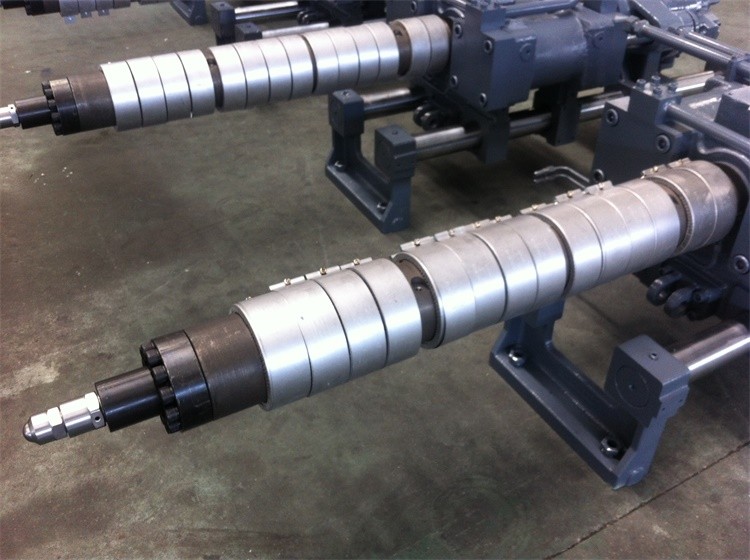

CST530-Ⅱ/3800 injection molding machine

Detail Information

CST530-Ⅱ/3800 | ||||

A | B | c | ||

Injection Unit | ||||

Screw diameter | mm | 80 | 85 | 90 |

Screw L/D ratio | L/D | 21.3 | 20 | 18.9 |

Injection capacity in theory | cm3 | 2110 | 2382 | 2670 |

Injection weight(ps) | g | 1920 | 2168 | 2430 |

oz | 67.7 | 76.4 | 85.7 | |

Injection pressure | MPa | 188 | 167 | 149 |

Injection rate | g/s | 437 | 494 | 571 |

Plasticizing capacity | g/s | 62 | 71 | 82 |

Screw speed | rpm | 130 | ||

Clamping Unit | ||||

Clamping force | kN | 5300 | ||

Moving mould-plate stroke | mm | 830 | ||

Max.Mould height | mm | 830 | ||

Min.Mould height | mm | 330 | ||

Space between tie-bars | mm | 860x810 | ||

Hydraulic ejector force | kN | 181 | ||

Hydraulic ejector stroke | mm | 230 | ||

Ejector number | n | 17 | ||

Other | ||||

Pump pressure | MPa | 16 | ||

Motor/Driving power | kW | 55/30x2 | ||

Heating capacity | kW | 28.85 | ||

Machine dimension | m | 8.35x2.14x2.57 | ||

Machine weight | t | 20.5 | ||

Oil tank capacity | L | 1156 | ||

Supply Ability

Supply Ability: 400 Set/Sets per Month

Packaging & Delivery

Packaging Details : Wooded pallet package, standard ocean shipping package of injection molding moulding machine

Port : Shanghai Port/Ningbo Port

Lead time: 30-45day

Machine Feature

1 Enhanced clamping mechanism to meet requirements for efficient production.

2 Excellent clamping features with optimized linkage mechanism to have faster and smooth operation.

3 Professional plasticizing unit is applicable for production of various raw materials, and to improve plasticize performance significantly.

4 Excellent injection performance with twin-cylinder injection mode, have more reliable and stable performance.

5 Professional platen optimization, the platen after finite element analysis and optimization has high rigidity and strength.

6 Centralized lubrication system with reliable protective configuration, quantitative distribution and centered lubrication,

provide more professional lubrication protection and extend mechanical life.

7 New frame type structure, simple and clean appearance, with more reasonable stress on machine body and high rigidity.

subscription

Company

Categories

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

Mobile Web