36 Krypton first release to realize the industrialization of 3D printing technology in the mold industry

36 Krypton first release to realize the industrialization of 3D printing technology in the mold industry

The mold industry is a basic upstream industry in contemporary manufacturing and is known as the "mother of industry". About 80% of the world's parts and components are produced through molds. According to statistics from the China Die & Mould Industry Association, the total output value of China's mold industry in 2019 exceeded 270 billion yuan, and there were about 30,000 mold manufacturing companies nationwide with more than 1 million employees. This led to the total output value of downstream parts products exceeding 3 trillion yuan. Although China's mold industry is huge, it faces problems such as backward manufacturing level, small and scattered scale, and high dependence on labor. The operation efficiency of the entire mold industry chain is not high. As the upstream field of the industrial chain, the insufficient delivery capacity of "from mold to product" has dragged down the efficiency of China's overall industrial production.

Faced with the above-mentioned problems, the "Leader Technology" team believes that 3D printing technology can improve the quality and efficiency of the mold industry, and promote the digital transformation of the entire mold industry.

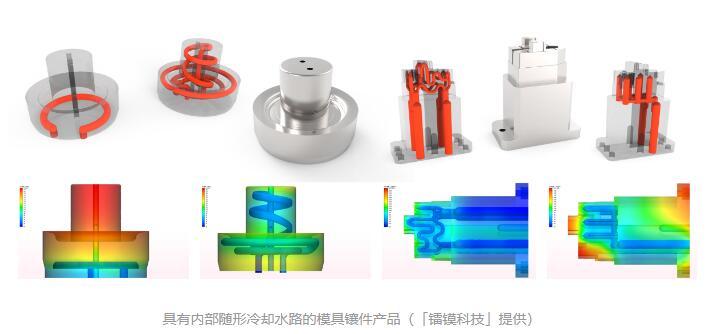

Different from traditional subtractive manufacturing (milling, milling, milling) and equivalent manufacturing (forging and casting) technologies, 3D printing is a more advanced additive manufacturing technology, and its core advantage lies in the ability to manufacture complex internal structures and external shapes; It can manufacture products with different structures and different quantities in batches at the same time, that is, mass customization; it can realize the shortest path from design to manufacture, which is a true digital manufacturing technology. Taking the service case of "Leading Technology" as an example, in the new face cream bottle packaging injection mold of an internationally renowned cosmetics company, after replacing the traditional mold with a 3D printing mold, the injection molding production efficiency has increased by about 42%, and the yield rate has increased by about 11%, the input-output ratio of 3D printing molds is about 1:5, which brings considerable economic benefits to users.

In terms of areas of focus, Zhang Guoliang, the founder and CEO of "Leading Technology", said that the company currently focuses on injection molds, which account for 45% of the mold market, and will expand its business in the field of die-casting molds in the future. In terms of sub-industries, the company currently focuses on five areas: auto parts, 3C consumer electronics, medical consumables, packaging for daily necessities and cosmetics, and home appliances.

In terms of cost of use, through process innovation and material innovation, "Laura Technology" has reduced the cost of using 3D printing molds to 50% of the industry average three years ago, and will maintain an annual decline of 10-20% in the next few years. According to Zhang Guoliang, this reduction in usage cost relies on the company's reduction in manufacturing costs, and the reduction in manufacturing costs is mainly due to the fact that "Radium Technology" has achieved full autonomy and localization of 3D printing materials through 8 years of hard work. Innovations in printing technology have improved printing efficiency. In the future, the company will steadily reduce the cost of use of the client while reducing manufacturing costs, thereby increasing user usage while maintaining a stable overall gross profit margin.

Due to the excellent performance and cost-effectiveness of the products, the 3D printing molds of "Leading Technology" have been widely used in well-known companies in many industries. In the 3C industry, the 3D printing molds of "Leader Technology" have entered the molding industry chain of Apple, Huawei, Xiaomi and OV; in the daily chemical industry, it has entered the product packaging molding industry chain of L'Oreal, Lancome, Estee Lauder, and Procter & Gamble; in the medical industry The industry has entered the medical consumables molding industry chain of Philips and Mindray Medical; in the automotive and home appliance industries, it has also provided 3D printing injection mold applications for some products of users such as BMW and Aux.

According to reports, "Leading Technology" achieved a revenue growth of about ten times in 2020 compared to 2019; it currently serves nearly 50 customers, of which 15 are major customers in sub-sectors.

Talking about the development plan for 2021, Zhang Guoliang said that the company will package the company's equipment, materials, and processes on the basis of existing printing manufacturing services to form an integrated solution "printing center", and begin to help customers build their own 3D printing manufacturing. Center, and obtain a new source of income by providing consumables and technical services. At the same time, the company will continue to increase market penetration in print manufacturing services, expand head customers, and increase investment in new materials, customized equipment, and software development. It is expected that in 2021, "Leader Technology" will achieve a 4-5 times growth in performance.

In terms of judging the development trend and competition pattern of the industry, Zhang Guoliang said that he began to explore the application of 3D printing technology in the mold industry in 2012. The main competition in the market during the past eight years did not come from peers, but from the tradition of the mold industry. Competition between manufacturing technologies. After eight years of verification of the application of 3D printing technology in the mold industry, the market has initially completed risk acceptance, value recognition and cost reduction. It is expected that the next five years will enter a golden development period of rapid increase in 3D printing technology penetration. At this stage, more competition in the industry will come from peers. The core advantage of "Leader Technology" lies in its in-depth understanding of the needs and product characteristics of the subdivided areas it focuses on, as well as more targeted R&D innovation based on this understanding. Generally speaking, it is to exchange understanding of the market for better technology, and use better technology to win more market share.

In addition, in the future, "Leader Technology" plans to cover the 3D printing software business on the upstream mold design side after solving the three major manufacturing problems of equipment, materials, and processes, and to carry out key research on the 3D printing smart factory operation system to solve the problems of mold companies. Design problems, operational problems, and delivery problems to improve the supply chain efficiency of the entire industrial production.

In terms of the founding team, Zhang Guoliang, the founder and CEO of "Leading Technology", graduated from Renmin University of China and Fudan University, and has many years of experience in manufacturing business operations and management; co-founder and CTO Yu Pengchao graduated from Central South University, a leading professional in China Majoring in metal materials, once held core technology R&D and management positions in internationally renowned steel companies and well-known 3D printing materials technology companies in Sweden, and has rich practical experience in metal powder bed fusion (PBF) 3D printing process.