Is the gap between domestic vertical injection molding machine and imported vertical injection molding machine large?

Is the gap between domestic vertical injection molding machine and imported vertical injection molding machine large?

I would like to say that it is now 2020, vertical injection molding machine production technology is not very difficult.So the gap between domestic vertical injection molding machine and imported vertical injection molding machine is not so big.Of course, there are several aspects to this argument.Still need to explain a point is that the domestic vertical injection molding machine said here is to point to the big manufacturers, not the products of small manufacturers.

between domestic vertical injection molding machine and imported vertical injection molding machine is not so big.Of course, there are several aspects to this argument.Still need to explain a point is that the domestic vertical injection molding machine said here is to point to the big manufacturers, not the products of small manufacturers.

Undeniable is, the public praise of vertical injection molding machine of domestic brand should be inferior relatively for certain, this is to must face, and public praise this thing is not a short time to be able to establish.For example, Japan's Japanese essence, Taiwan's today's machine are more domestic use of imported brands.Their machines are characterized by their high price, durability, and lack of breakdowns and minor faults.

Domestic vertical injection molding machine is the main parts also are basically choose Japanese brands, such as vertical injection molding machine control system is generally choose mitsubishi or panasonic, their programming control system for high maturity, high precision, easy to operate, holds a large share in the market, and the import of vertical injection molding machine programming system is mostly the two brands.So in terms of operational and control accuracy the difference here is small.

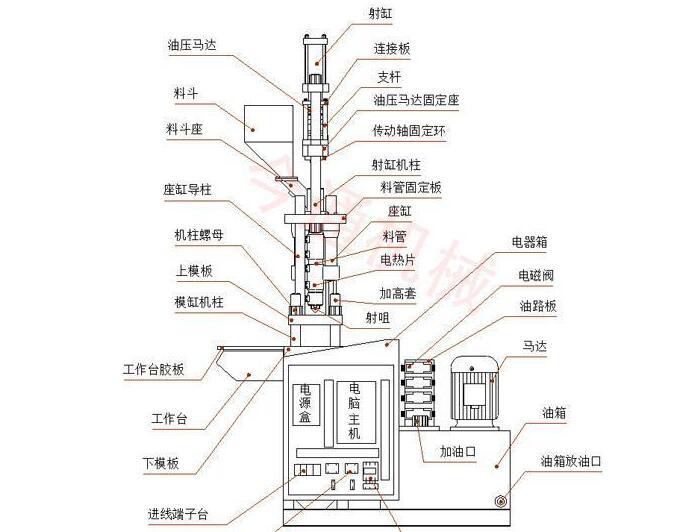

From the accessories, the injection molding machine's various accessories are not difficult, also do not need so high production technology, such as common screw, machine stand, machine column, cylinder, hopper.Many of these mold factories are able to process production, so the gap here is not very big.

The main difference to, such as the motor, hydraulic cylinder, pressure cylinder and so on this has worn out parts or wear parts is the most prone to problems, many customers do not know that in fact easy to wear out parts appear small problems because of their poor maintenance, is not the brand department line.And the precision of all kinds of pressure cylinder of the imported Japanese brand itself is made very well and the price is expensive, in order to commonly used in mechanical fixture jig with hydraulic cylinder, hydraulic cylinder and so on are the best in Japan, the price of a single cylinder in 3000-5000 are the cheapest.And domestic brands because of the low price will mostly have worn out parts to choose domestic hydraulic cylinder accessories.

Some vertical injection molding machine time is longer manufacturers basically control the quality of their products are very good, and even if there are problems will have after-sales service, so actually the gap is not very big, how to see your own choice.