How to make the shell mould of daily necessities?

How to make the shell mould of daily necessities?

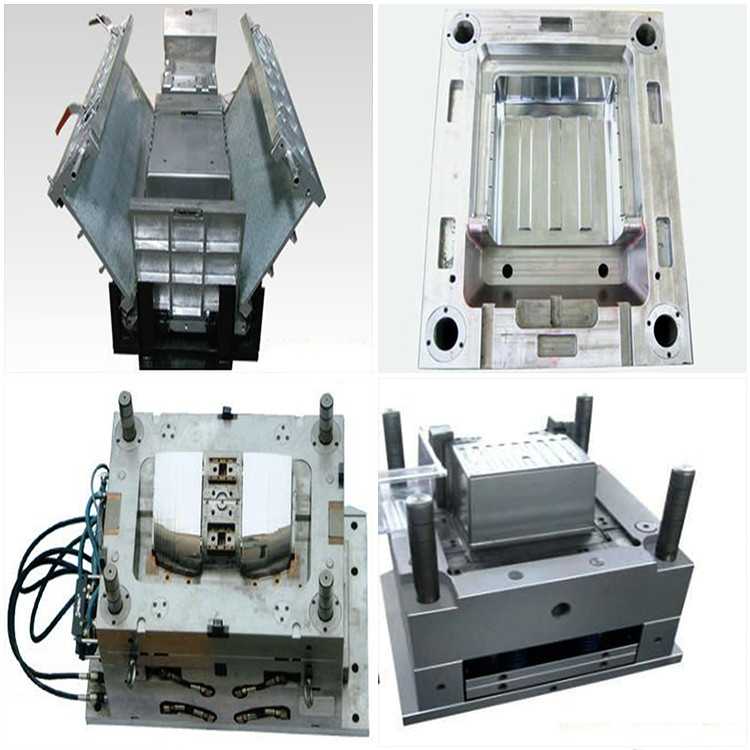

There are many Mold for life products in our daily life, such as printers, telephones and so on. Do you know how these beautiful shell shapes are made?

In fact, These daily necessities molds are made by the injection molding process, but before injection molding, we need to use this tool to make the mold shells for daily necessities-the mold shell molds commonly used for daily necessities. The manufacturing of the mold is very particular! Please listen to me carefully.

3D product drawings are essential for custom die making.Typically, they are provided by the customer.If the customer does not have paper, they can also ask the industrial product design company to help with the design.After mastering the main content, the next is the injection mold factory main processing process.

Mold for life products shell mold factory general mold engineer requirements are particularly high, that is because the engineer is to lay the foundation of Mold for life products shell mold quality.For the quality of the product, set up the mold with reasonable structure and use reasonable materials.Only in this way, a set of molds can be completed, so that the subsequent production can be completed more smoothly, and can be designed to produce high-quality products of the mold!No worries.

The quality of Mold for life products, mould quality determines the quality of products, and mould is the matrix of products.For example, if the product has batch peaks and burrs, then the time to repair the product will increase a lot.But if the mold can eliminate quality problems, it can increase productivity and save labor.Therefore, the quality of the mold is very important.