Design of the mold cooling circuit is very important

Cooling pipework

Design of the mold cooling circuit is very important because it will work as a heat exchanger that cools the resin when molding. Aboutφ8~12mm is preferred for the diameter of the mold cooling hole. Its location should be near the cavity face as possible, and try to make the distance between cooling holes shorter as possible.

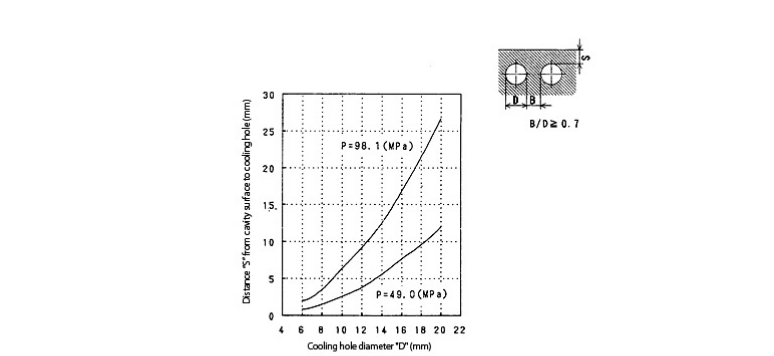

Shortest distance from the cavity surface to the cooling hole will be decided by the mold material, cooling hole

dimension, shape, and cavity inner pressure.

Figure 2-14 indicates relation between cooling hole distance from the cavity surface and cooling hole dimension. This curve calculates the diameter of the cooling hole, presuming the cavity surface will elastically change by 2m. As a rule of thumb, distance between cooling holes should be taken more than 0.7 times of the cooling hole diameter.

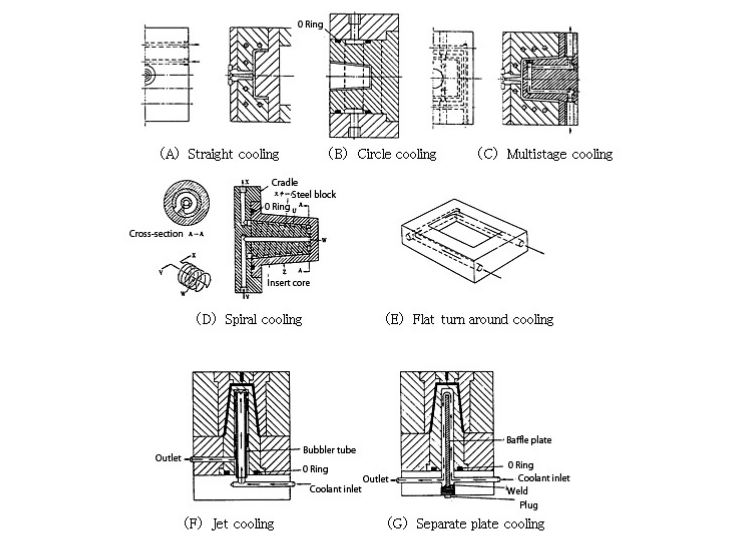

However, this kind of layout is very difficult on the actual mold, so the actual mold is composed of combination

of various cooling circuit. If we are to classify the cooling circuits, there will be straight, circle, multistage, spiral,

flat turn around, jet (bubbler tube), separate plate (baffle plate), and etc. (Figure 2-15)

Also, partly replacing the mold material with the material which has better heat conductivity is one method for

the part where placing cooling flow passage is difficult.

Figure 2-14 Relation of distance from cavity surface to cooling hole and cooling hole dimension

Figure 2-15 Examples of cooling circuit structure